Making of different type of Metallic French wire for Embroidery & Jewelry embellishments.

Original French wires were made from real silver and gold bars in earlier times. But with pricing going up the alloy metal got changed.

These days you will get French wires made from Iron or from Copper alloys. Never buy metallic wires made from Iron because they rust very fast and doesn’t have long shelf life. You can always find out about it by simple magnate test.

These days you will get French wires made from Iron or from Copper alloys. Never buy metallic wires made from Iron because they rust very fast and doesn’t have long shelf life. You can always find out about it by simple magnate test.The metallic wires made from copper are the best but they

also have different quality standards. For ex: - silver metallic wires are best

in shine and consistency when it has 10% real silver and remaining 90% copper. The silver metallic wire is usually the most

expensive one in the lot. The manufacture must know that how much amount of

silver to add in making wires because silver has a basic quality of turning

black with time if its not polished regularly. So, that’s why the metallic wires

shouldn’t be made from high consistency of silver also.

Other color wires like gold, black, green; blue also has

some percentage from 5% to 7% of silver in them and remaining copper metal.

The basic color of metallic wire is copper and other colors

are given through electroplating process. The colors given through this process

are consistent throughout the metallic wires. Always change the water and clean

the vessel properly after a single lot of color processing otherwise you will

see a pinch or shade of earlier color in your new color development. Other

cheaper way to give color is dying process. It’s similar to dying of fabrics.

The colors given through this process are dull, inconsistent and can bleed

after washing.

Copper Wire before electroplating & Electroplating process

So, in nutshell we can say that metallic wires made from silver and copper alloy with electroplating process are best to use for jewelry making and doing surface embroidery for high couture wears.

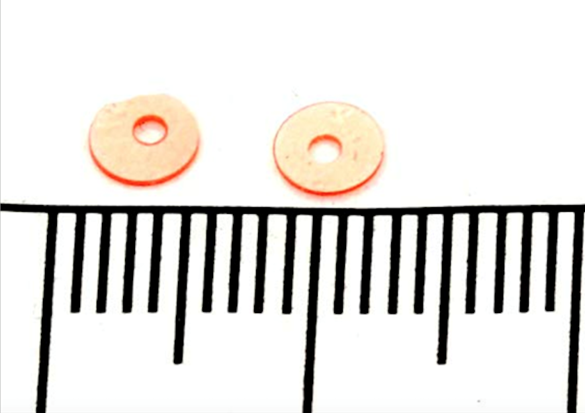

Now, the surface of metallic wires has also evolved with time. With smooth surface, you can get crinkled, embossed, purl, pearl purl and many more variations according to your choice. All these shapes are given at the time of coiling the simple plain copper wire around the needle.

If the coiling is not done properly then you will see gaps in the metallic French wire string. So, it’s very important that the whole lot of French wire is made at a consistent speed of coiling.

Comments

Post a Comment